We provide qualified personnel who are certified in accordance with API 510 to carry out inspection of pressure vessels. Our inspection plan is developed from the analysis of several sources of data. Equipment shall be evaluated based on present or possible types of damage mechanisms. The methods and the extent of NDE shall be evaluated to assure they can adequately identify the damage mechanism and the severity of damage. Examinations of the vessel seek to identify Type of damage, rate of damage progression and tolerance of the equipment to the type of damage.

We select and mark proper Corrosion Monitoring Locations at which subsequent inspection shall be done in order to ensure that thickness readings obtained over the years are comparable.

Among techniques we use for inspection are;

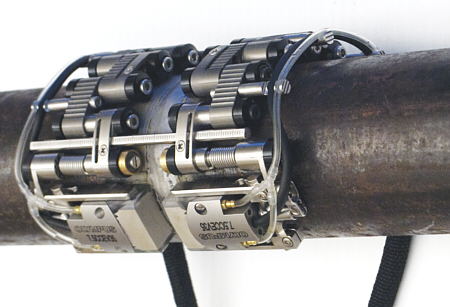

- Ultrasonic Thickness Survey

- Ultrasonic Flaw Detection for Welds

- Magnetic Particle Inspection to identify cracks

- Pitting Gauge

Our inspection report provides details of findings on the visual condition of the vessel, thicknesses of the components, available corrosion allowance, a calculation of Maximum Allowable Working Pressure, next inspection date and recommended setting of pressure relief devices. In case of any repairs recommended, we provide proper guidance to our clients.