As the world grapples with the pressing issue of climate change, industries and researchers are continually seeking innovative technologies to mitigate environmental impact. One such technology making a significant contribution is Phased Array Ultrasonic Testing (PAUT). Though primarily known for its applications in the field of non-destructive testing (NDT), PAUT is proving to be an invaluable tool in our efforts to combat climate change. Here’s how.

Understanding Phased Array Ultrasonic Testing

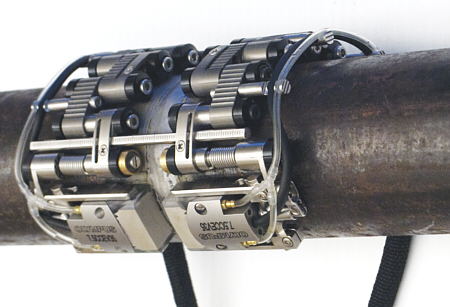

Phased Array Ultrasonic Testing is an advanced method of ultrasonic testing that uses multiple ultrasonic elements and electronic time delays to create beams of sound waves. These sound waves can be steered, focused, and scanned electronically, allowing for detailed imaging of internal structures. This technology is highly precise and versatile, making it ideal for inspecting complex geometries and materials in various industries.

Enhancing Renewable Energy Infrastructure

One of the critical areas where PAUT contributes to fighting climate change is in the enhancement of renewable energy infrastructure. Wind turbines, solar panels, and hydroelectric plants all require rigorous quality control and maintenance to operate efficiently and safely. PAUT enables detailed inspection of these structures, ensuring they are free from defects and can operate at peak efficiency.

- Wind Turbines: Regular inspections using PAUT can detect internal flaws in turbine blades and towers, preventing catastrophic failures and ensuring longevity. This helps maintain continuous energy production and reduces downtime, contributing to a more reliable renewable energy supply.

- Solar Panels: PAUT is used to inspect the structural integrity of solar panels, ensuring they are free from micro-cracks and other defects that could impair performance. This maximizes energy output and extends the lifespan of solar installations.

- Hydroelectric Plants: PAUT can be employed to inspect the integrity of dams and underwater structures, preventing leaks and ensuring safe operation. This is crucial for the sustainability and safety of hydroelectric power generation.

Reducing Industrial Emissions

Industries are major contributors to greenhouse gas emissions. By employing PAUT, industries can reduce emissions through improved maintenance and efficiency.

- Pipeline Inspections: PAUT is extensively used in the oil and gas industry to inspect pipelines for corrosion and cracks. Early detection of defects prevents leaks and ruptures, reducing the risk of oil spills and gas leaks, which have severe environmental impacts.

- Power Plants: In power generation plants, PAUT is used to inspect boilers, turbines, and other critical components. Ensuring these components are in optimal condition improves efficiency and reduces fuel consumption and emissions.

Supporting Sustainable Manufacturing

Sustainable manufacturing practices are essential for reducing the carbon footprint of industries. PAUT supports these practices by ensuring the integrity and reliability of manufacturing equipment and products.

- Automotive Industry: PAUT helps in the production of lightweight and durable components for electric and hybrid vehicles, contributing to lower emissions. High-quality components also mean longer-lasting vehicles, reducing waste and resource consumption.

- Aerospace Industry: By ensuring the integrity of aerospace components, PAUT contributes to the production of more efficient aircraft. This leads to reduced fuel consumption and lower emissions, making air travel more sustainable.

Extending the Life of Existing Structures

PAUT plays a vital role in the maintenance and life extension of existing infrastructure, which is crucial for sustainability. By detecting and addressing defects early, PAUT helps avoid premature replacements and reduces resource consumption.

- Bridges and Buildings: Regular inspections using PAUT ensure the safety and durability of bridges and buildings, preventing structural failures and extending their life. This reduces the need for new construction and the associated environmental impact.

- Railways: PAUT is used to inspect railway tracks and components, ensuring safe and reliable transportation. This promotes the use of rail transport, which is more energy-efficient and environmentally friendly compared to road transport.

Phased Array Ultrasonic Testing is a powerful tool in the fight against climate change. By enhancing the efficiency and safety of renewable energy infrastructure, reducing industrial emissions, supporting sustainable manufacturing, and extending the life of existing structures, PAUT contributes significantly to environmental sustainability. As industries continue to adopt and innovate with this technology, its role in combating climate change will only grow more substantial, paving the way for a greener and more sustainable future.