We perform in-service and out-of-service inspection of aboveground storage tanks in accordance with API 653 inspection checklist as provided in Appendix C of the standard. Techniques employed in inspection include the following NDT methods;

We perform in-service and out-of-service inspection of aboveground storage tanks in accordance with API 653 inspection checklist as provided in Appendix C of the standard. Techniques employed in inspection include the following NDT methods;

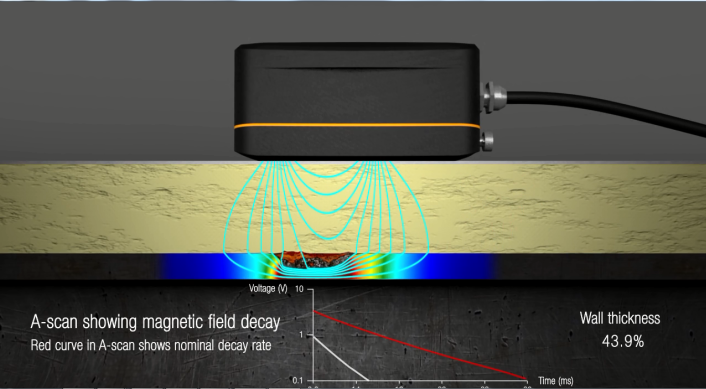

- Magnetic Flux Leakage Inspection (MFL) of the bottom plates to establish percentage metal loss with top and bottom defect discrimination

- Ultrasonic Thickness (UT) measurement to establish remaining thickness of shell, bottom, roof plates and nozzles. We use a magnetic crawler to avoid scaffolding requirement for shell UT

- Vacuum Box testing (VB) of lap welds to detect for leaks

- Dye Penetrant Test (DPT) in areas suspected to have cracks or pinholes

- Pit gauging to determine depth of localised corrosion metal loss

- Tank bottom and shell settlement evaluation

- Tank Tilt and Out of Roundness

Non- Destructive Testing (NDT) Services for detailed description of these techniques Using inspection results from a combination of these techniques, we establish the corrosion rate and remaining life of the tank shell/ bottom/ roof plates.

As we evaluate the condition of your asset for its suitability for continued use, we strive to improve its technical integrity by identifying and eliminating risks. We assist our esteemed clients in preparation of proper equipment records and schedule for external /internal inspection of the tanks using the tank history, current condition and extrapolation of the trends.

Our API 653 certified inspectors have extensive experience in construction and repair of Storage tanks constructed to API 650 and equivalent standards. Coupled with our engineering background and prowess in use of standards/ codes for best engineering practices in the industry, we have remarkable technical knowhow in assessment of tanks to review construction and design of storage tanks and determine compliance to the construction standard

Our assessment covers minimum thickness calculations, tank stability and stiffening requirements and maximum filling heights for corroded tanks. We give recommendations for repairs and possible extension of the equipment life in the most cost effective methods.