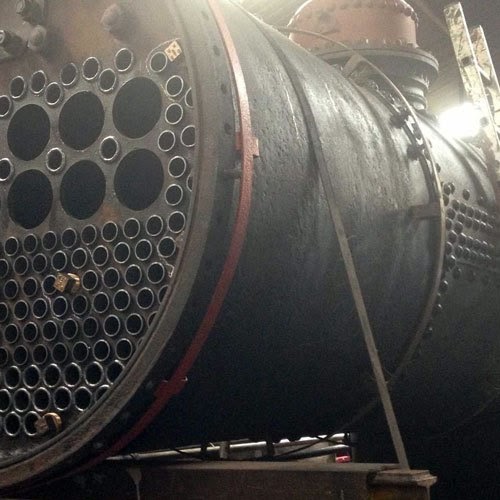

Boilers and Furnaces are subject to regular statutory inspections and testing, with non-destructive testing (NDT) required every 5 years. This is necessary to ensure safe and reliable operations of your equipment. Our personnel have vast experience in boiler inspection, and we provide Third Party Quality Assurance and Quality Control Services during repairs, modification and maintenance. Our intervention includes visual inspection for internal corrosion and Corrosion Under Insulation, UT survey of the boiler shell and tubes, MPI inspection of critical welds of the boilers for identification of cracks and Ultrasonic Flaw Detection.  We also perform Hydrostatic Testing of such equipment.

We also perform Hydrostatic Testing of such equipment.

We also employ advanced NDT techniques such as Pulsed EddyCurrent (PEC) technique to establish the remaining wall thickness of the boiler shell, without need for removal of insulation. See this link for a demonstration of PEC technique; https://youtu.be/s7ORHhhCtyk and https://youtu.be/4YEc-XyQ5Ww

This provides for a fast, reliable and affordable way of assessment of our clients equipment while eliminating the need for insulation removal and reinstatement.

We carry out inspection of heat exchangers for corrosion and leakages, both for the tubes and the exchanger shell. Besides the use of the NDT techniques listed above, we also perform hydrostatic testing of the heat exchangers. Our personnel are proficient in supervision of exchanger re-tubing and inspection to standard.